From Concept to Development: Releasing Creativity With DTF Printing on Different Fabrics

In today's dynamic world of textile layout, the use of Direct to Movie (DTF) printing innovation has changed the process of moving complex designs onto different fabrics. The blend of development and virtuosity with DTF printing opens up doors to a realm where creative imagination understands no bounds.

Exploring the Conveniences of DTF Printing

One vital advantage of DTF printing is its convenience in terms of the textiles it can be used to. Unlike some conventional methods that are limited to specific fabric types, DTF printing can be utilized on a large array of materials, including cotton, polyester, blends, and even leather.

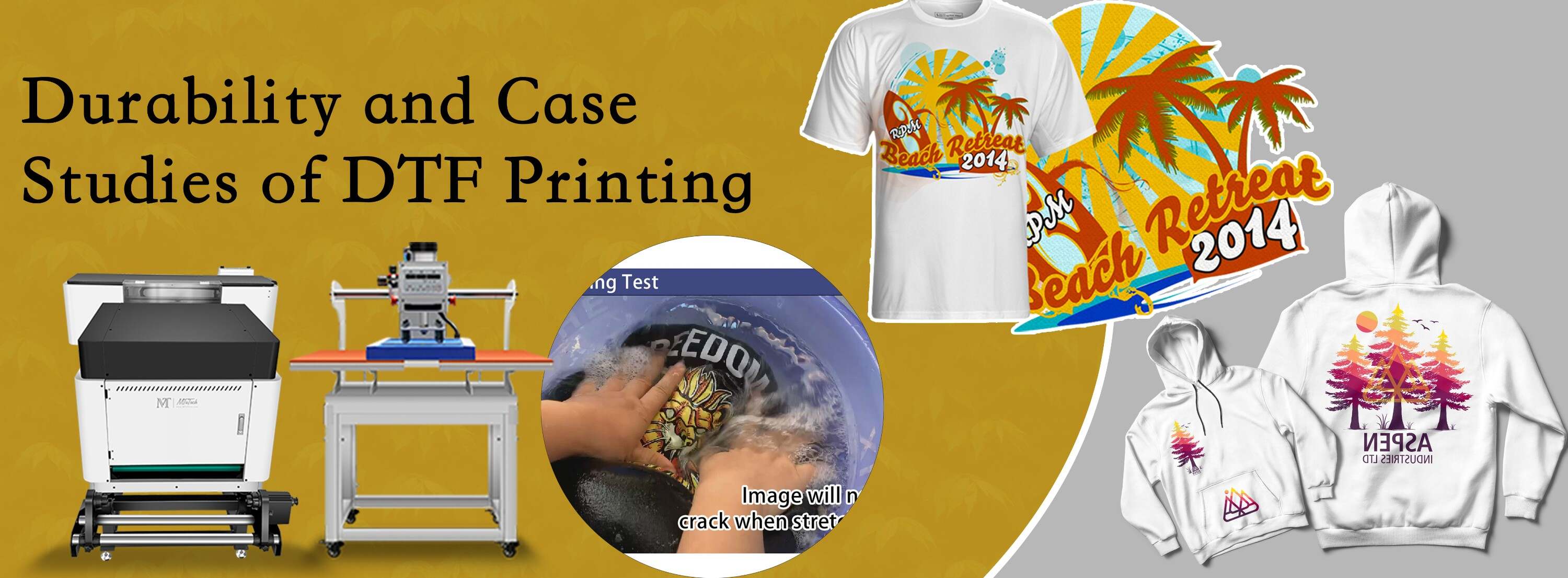

Additionally, DTF printing uses exceptional resilience, making it suitable for generating long-lasting designs on textiles - DTF Printing. The prints created through DTF are known for their vibrant shades and resistance to fading, cracking, or peeling off - ensuring that the final product maintains its quality even after numerous cleans or expanded usage. This longevity makes DTF publishing an affordable solution for manufacturers aiming to develop top quality, long lasting designs on fabrics

Creating With DTF: Advice

Creating successfully with DTF printing involves mastering the details of digital layout software and recognizing exactly how to optimize layouts for the very best results on various fabrics. When developing styles for DTF printing, it is crucial to take into consideration the material structure, kind, and shade to ensure that the last product fulfills expectations. Below are some suggestions and tricks to improve your DTF layout procedure:

Resolution is Secret: Start with high-resolution pictures to keep clarity and intensity in your designs. Low-resolution pictures can result in a pixelated end product.

Color Matching: Take notice of color accuracy when designing for DTF printing. Use shade monitoring tools to ensure that the colors in your layout translate properly onto the material.

Vector Videos: Utilize vector graphics anywhere feasible to keep the top quality of your styles when scaling them to various dimensions. (DTF Printing)

Test Prints: Always perform examination prints on sample textiles to examine the colors, resolution, and general style top quality prior to major manufacturing.

Choosing the Right Fabrics for DTF

When considering the ideal materials for DTF printing, the selection of material plays an essential function in attaining the wanted quality and toughness of the last published designs. Selecting the best material is crucial for ensuring that the shades adhere well, the style remains sharp and dynamic, and the total appearance satisfies assumptions. Fabrics with a high polyester web content are generally chosen for DTF printing because of their capability to hold the ink well and produce vivid prints. Polyester blends can also work efficiently, providing a balance between resilience and print high quality. Additionally, fabrics with a smooth texture tend to generate better results as they provide a consistent surface for printing, enabling accurate describing and shade precision. It is necessary to think about the desired use the published textile when choosing the material, as various materials offer differing degrees of navigate to these guys breathability, washability, and stretch. By very carefully choosing the right textile for DTF printing, developers can enhance the longevity and aesthetic impact of their layouts.

Step-by-Step DTF Printing Process

After curing, the published style is then moved onto the textile making use of a warmth press. Once the transfer is full, the material is enabled to cool down before the transfer film is peeled off, leaving behind the vivid and long lasting layout on the material.

Showcasing DTF Masterpieces

Have you ever marveled at the intricate details and dynamic colors of DTF masterpieces showcased on different fabrics? DTF printing has actually transformed the way designs are transferred onto fabrics, allowing for unrivaled accuracy and richness in colors. When these DTF masterpieces are placed on display, they astound audiences with their striking visuals and thorough craftsmanship.

Among the most exciting elements of showcasing DTF work of arts is the flexibility it offers. Whether it's a eye-catching and vibrant style on blog here a t-shirt, an in-depth pattern on a pillow case, or a custom-made print on a canvas bag, DTF printing enables unlimited possibilities. This versatility allows musicians and designers to release their creativity and bring their visions to life on a wide variety of textiles.

Furthermore, the longevity of DTF prints makes certain that these masterpieces can endure the test of time without shedding their vibrancy. Whether displayed in galleries, worn as classy garments, or used as ornamental accents in homes, DTF work of arts remain to impress customers with their remarkable high quality and aesthetic allure.

Verdict

In conclusion, DTF printing offers a cutting-edge and flexible approach for letting loose creative thinking on numerous textiles. By checking out the advantages of DTF printing, creating with certain pointers and methods, picking proper materials, and complying with a step-by-step printing procedure, musicians can display their work of arts effortlessly. This process allows for the smooth change from idea to development, supplying limitless possibilities for creative expression.

In today's vibrant world of textile i was reading this design, the application of Straight to Movie (DTF) printing modern technology has actually changed the procedure of transferring intricate layouts onto numerous textiles.Designing efficiently with DTF printing entails understanding the ins and outs of digital layout software program and recognizing exactly how to optimize layouts for the finest results on numerous materials.When thinking about the ideal fabrics for DTF printing, the selection of material plays an important role in attaining the desired high quality and toughness of the final published styles. The following step is publishing the design onto an unique DTF transfer film using a DTF printer with the proper ink. By checking out the benefits of DTF printing, making with particular pointers and tricks, picking proper textiles, and complying with a detailed printing process, artists can display their masterpieces with simplicity.

Comments on “DTF Printing Proficiency: Raise Your Textile Creations with Direct-to-Film Innovation”